Popular Products

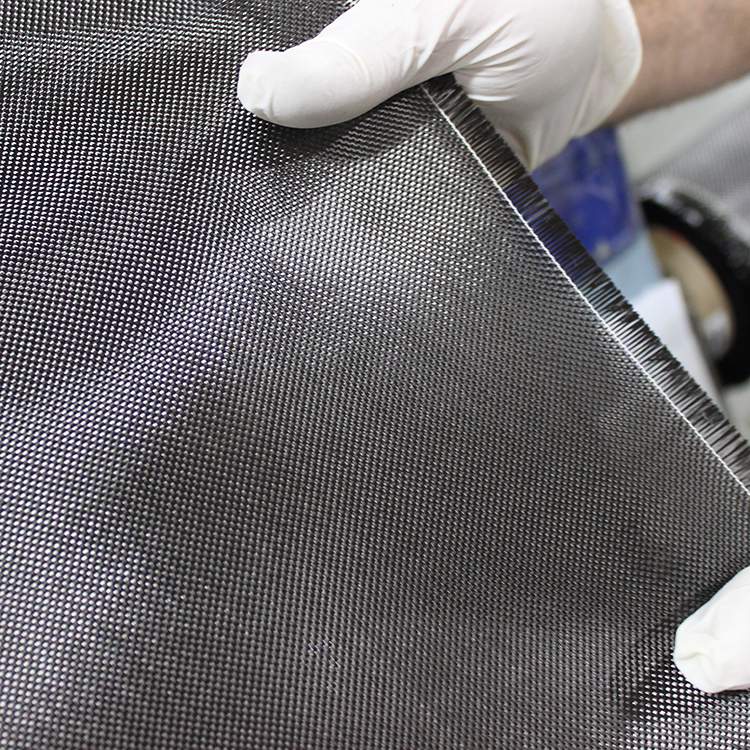

Carbon Fiber Sheet

We, Shanghai Hongwei New Tech, have sold the carbon fiber sheet, which is from a leading domestic manufacturer.

In the production process, the yarn is produced by constant tension control, and the fiber bundle is straight.

Adopting an effective shaping process, there is no loose deformation when the fabric is cut, it is easy to spread the glue, and convenient for the construction.

Our Products

Fire Retardant

Global Procurement and Sales Network

1

+

Successful Case

1

+

Customer Satisfaction

1

+

Enterprise's Patent

1

+

Multinational Procurement and Sales

Most of our products are imported from abroad, with a good reputation and quality to sell. We guarantee we will provide high quality, favorable prices, and efficient customer service, using procurement, marketing, sales, and distribution systems, covered by the worldwide network.

We have a professional team of engineers, which definitely gives practical guidance to clients on familiarizing products and manufacturing processes in the shortest time, and improves their competitiveness.

Business Consulting

Please leave your contact information below, so we can contact you immediately.

FAQ

Carbon fibers are composed of a diameter of 5 to 10 microns fiber bundles, which are made up of a long and dense chain of carbon atoms in a microscopic crystal structure. These fibers are very hard, strong, and lightweight, which are widely used in various applications that require excellent strength, rigidity and low weight.

- High strength and lightweightCarbon fiber is one of the strongest and lightest composite materials, 30-40% lighter than aluminum, and the strength is 5 times higher than steel with the same weight, which makes it very popular in many industries.

- High tensile strengthCarbon fiber has the highest strength among all commercial reinforcing fibers, and it is very hard to stretch or bend.

- Excellent durabilityCompared with metal, carbon fiber has excellent fatigue properties, which means component parts made of carbon fiber will not be abraded quickly under the pressure of sustained use.

- Low thermal expansionCompared with steel, aluminum and other materials, carbon fiber will not expand or contract when the temperature changes.

- AppearanceCarbon fiber has a particularly beautiful appearance that makes it widely used in many industries.

- Superior corrosion resistance and wear resistanceCarbon fiber has superior corrosion resistance and wear resistance, ensuring its long service life.

- Good conductivityCarbon fiber composite materials with good conductivity are highly efficient conductors of electricity.

- RadiolucencyCarbon fibers are radiolucent, invisible in X-rays, practical value in medical equipment and facilities.

"3k" means that each fiber bundle of carbon fiber fabric is composed of 3000 individual carbon filaments. A bigger number (6k, 12k, etc.) means that the carbon fiber fabric has a thicker fiber bundle, which constitutes heavy fabric.

- Twill weavingis the most commonly used method, having diagonal grain with a certain angle in the configuration and direction of the fiber bundle. There is no fiber bundle in the grain’s direction, but during the warp and weft weaving process, the warp or weft fiber bundle skips two weft or warp fibers to weave. That means, the weaving frequency of the fiber bundle up and down decreased, and the floating length of the fiber bundle increased, simultaneously, the two adjacent fiber bundles are staggered by one weaving position, producing the diagonal grain, the characteristic of twill weave fabric. In addition, it has a strong third dimension of appearance, a more uniform strength, and is suitable for production with higher requirements, such as automobile products, sports equipment, etc.

- Plain weavingis the second most widely used among fabrics, characterized by the regular interweaving of warp and weft yarns. That is to say, the warp and weft yarns are staggered every other yarn, so there are the most interlacing points that make the fabric firm, wear-resistant, stiff, smooth, and lightweight, except less elastic. The plain weave fabric has good air permeability, and the surface is even and uniform, with the same two sides. Besides, the fiber bundle is always in a state of up and down, with more fiber bending points, and the elongation rate is higher during the stretching process.

- Unidirectional weavingUnidirectional carbon fiber cloth refers to a large number of carbon fiber filaments in one direction (usually the warp direction), and a small amount generally in the other direction, which the whole strength is in the same direction. Normally for applications where all force on parts are in one direction.

Office Address

Room 15L, No. 726, Hua Min Han

Zun Guo Ji, Shanghai, China

Zun Guo Ji, Shanghai, China

Call for Help

18516699210

Mail for Info

sarah@hwnewtech.com