Description

Technical Indicators

| Type | Weight of original fabric(g/m2) | Thickness of original fabric(g/mm) | Resin content(%) | Gross weight of prepreg(g/m2) | Thickness of prepreg(mm) | Range(mm) | Volatility(%) |

| 10# | 80±4 | 0.09±0.01 | 34±2 | 121±3 | 0.12-0.16 | 1000±200 | ≤1 |

| 36±2 | 125±3 | 1000±200 | ≤1 | ||||

| 13# | 160±6 | 0.15±0.015 | 34±2 | 242±5 | 0.21-0.26 | 1000±200 | ≤1 |

| 36±2 | 250±5 | 1000±200 | ≤1 | ||||

| 18# | 220±8 | 0.20±0.02 | 34±2 | 333±7 | 0.26-0.31 | 1000±200 | ≤1 |

| 36±2 | 344±7 | 1000±200 | ≤1 | ||||

| 24# | 292±15 | 0.28±0.03 | 34±2 | 449±9 | 0.33-0.38 | 1000±200 | ≤1 |

Instrucyions

1) Take out prepreg from the refrigerator and defrost at room temperature (22℃) for 4 hours at least to use.

2) Rewrap unspent prepreg and store at a low temperature.

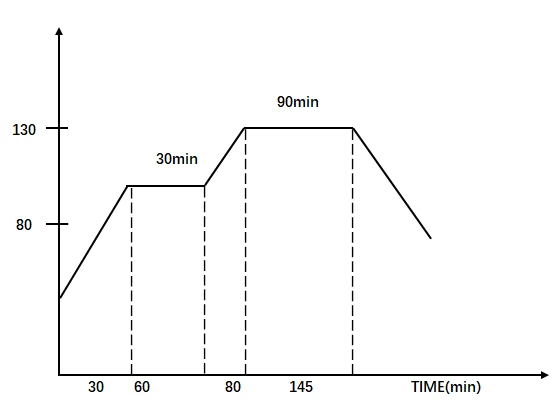

3) Recommended process:

Raise the temperature to 80℃ gradually and maintain for 30min, and then raise to 130℃ and maintain for 30min.

The furnace cooling to 60℃ and demould 2℃/min should be at the proper speed.

Attentions

1) The width of prepreg is 1000±20mm.

2) The resion content could be adjusted as client's request.

3) Thickness measurement: measure 4points along the cross sectional side line of prepreg and take the average.

4) Storage method:1 month at room temperature(22℃); 3months at -5℃

Reviews

There are no reviews yet.